Here are the services we offer

If you need a quote, we have a secure FTP site where you can upload your cad data for us to quickly respond with our competitive pricing.

Kellforms has been the Leader in precision patterns and moulds for the last 50 years, employing the finest design and craftsmen available to engineer patterns and moulds for complex instrument panels, complete automotive interiors, exterior body panels, aircraft components, and much more.

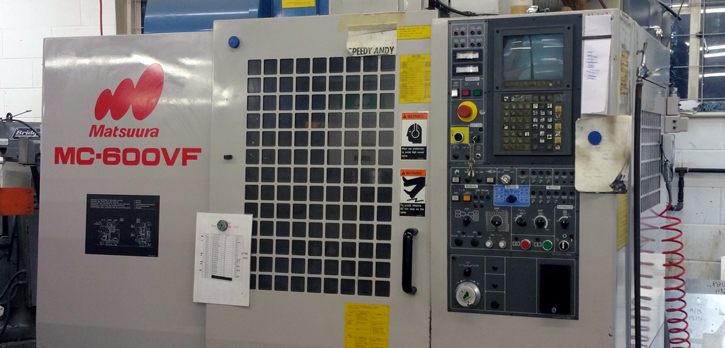

High levels of skill and expertise, combined with the use of the most sophisticated equipment and materials allow Kellforms to develop work of the highest quality without compromising on delivery or price. Providing unparalleled experience in all aspects of pattern and mould making and are used to working with a wide range of materials, from polystyrene through to the latest high temperature tooling resins.

Models of any size or detail can be built at Kellforms. A full array of models are available, including full-scale Models and patterns for the Automotive and Race car sectors, ranging in complexity from economical prototype models, to premium quality full scale models.

Utilising Delcam's advanced Powershape - Powermill Cad/Cam solution and highly skilled fixture design and manufacturing workforce, Kellforms can provide a total solution to satisfy a variety of fixture and gauging requirements.

With in-house design services, we are able to both design and manufacture manual and fully automated SPC checking fixtures, full attribute gauges, hand applied, assembly fixtures and CMM holding fixtures, and secondary tooling. Using our wide range of CNC machines and inspection services we can insure that we meet all of your accuracy and inspection requirements.

Our expertise is predominately focused on meeting the needs of the automotive, and aerospace sectors, for both plastic and sheet metal components ranging in size from small interior trim panel gauges through to full vehicle assemblies.

Whether it be full component design or a simple holding fixture Kellforms can produce a creative and practical design solution on time and within budget for a broad range of company sectors.

Our team of experienced design engineers will work closely with you to fully comprehend the required features, functionality and specifications that the product must meet. A detailed quotation will be provided for your acceptance before any actual design or manufacturing is performed.

We can design from an initial series of constraints, through to a third party CAD model supplied either of the component or the surrounding parts, supplying concept sketches, ergonomic and aesthetic visual models to prove styling utilising many different materials and methods of manufacture.

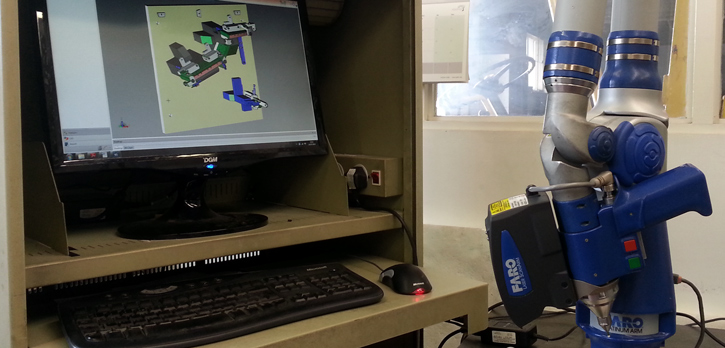

From individual component inspection to complete assembly jigs, Kellforms have built a reputation for innovation coupled with accuracy and consistent performance.

Attention to detail is a necessity throughout - particularly where the Inspection Department is concerned. Here, qualified inspectors use advanced computerised coordinated measuring equipment utilising the Faro CAM2 Measure 10 software, to make sure models, patterns and tools, as well as jigs and fixtures, are thoroughly checked to drawing specifications.

The result is repeatable accuracy - from small components to complete assemblies - with a fast, versatile and cost-effective service that gives Kellforms the competitive edge to meet every client's needs.